Why Choose Jeff Lilly Restorations?

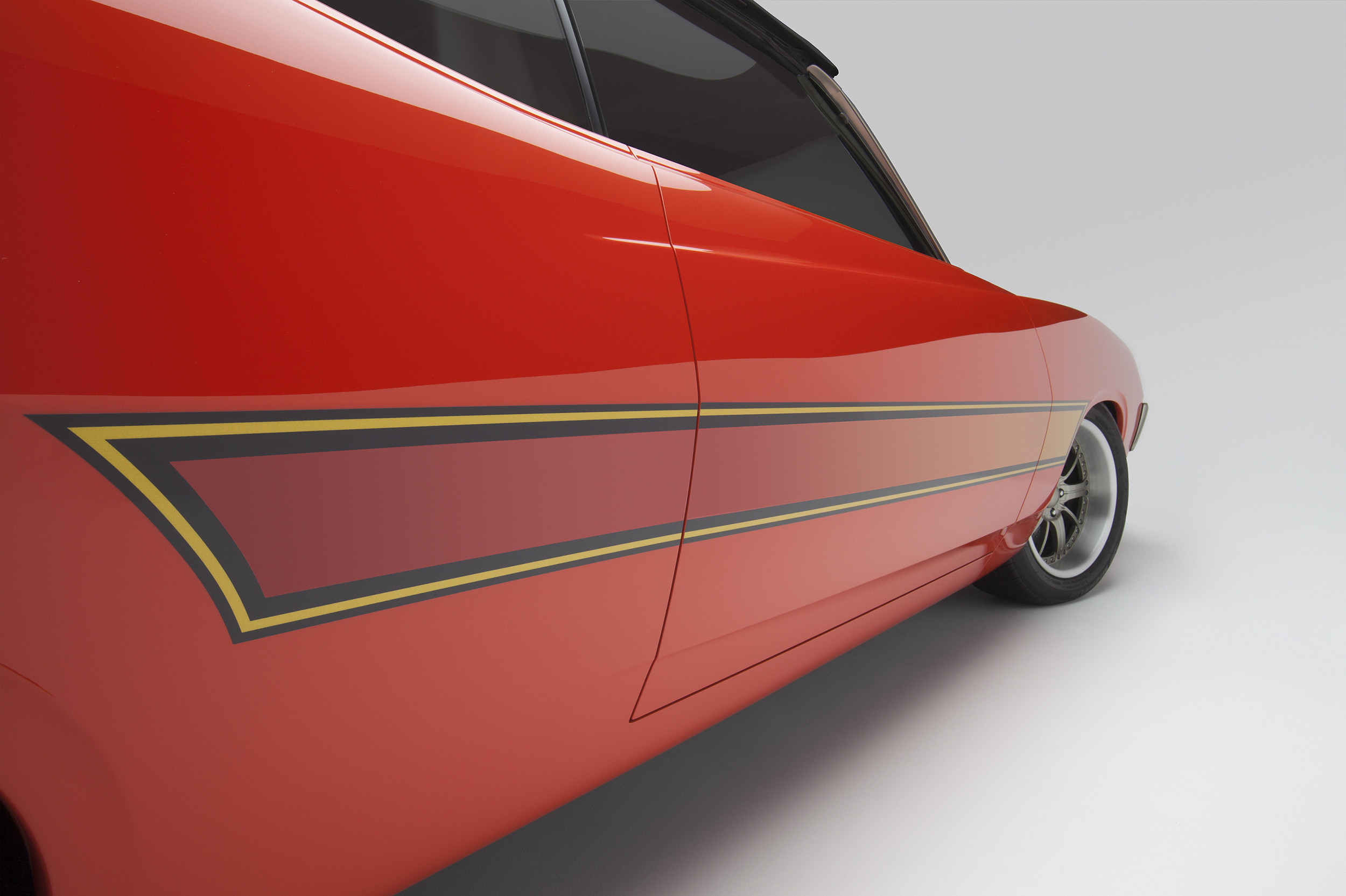

FLUSH FIT PANELS AND PRECISE GAPS ARE STANDARD ON ALL PROJECTS.

DO NOT SETTLE FOR ANYTHING LESS ON YOUR LIFE TIME DREAM.

DO NOT SETTLE FOR ANYTHING LESS ON YOUR LIFE TIME DREAM.

SEPARATE BODY PARTS WITH CURVED GAPS ARE 1/16TH WIDE AND RUN TRUE AROUND THE PERIMETER.

REFLECTIONS SO DEEP THEY CATCH YOUR EYE FROM EVERY ANGLE

WITH PRECISE METALLIC SEPARATION.

WITH PRECISE METALLIC SEPARATION.

ON CUSTOM PROJECTS TIGHT FIT BUMPER GAPS ARE A MUST.

1/16TH WIDE IS THE STANDARD.

1/16TH WIDE IS THE STANDARD.

Defining the line of Excellence since 1957.

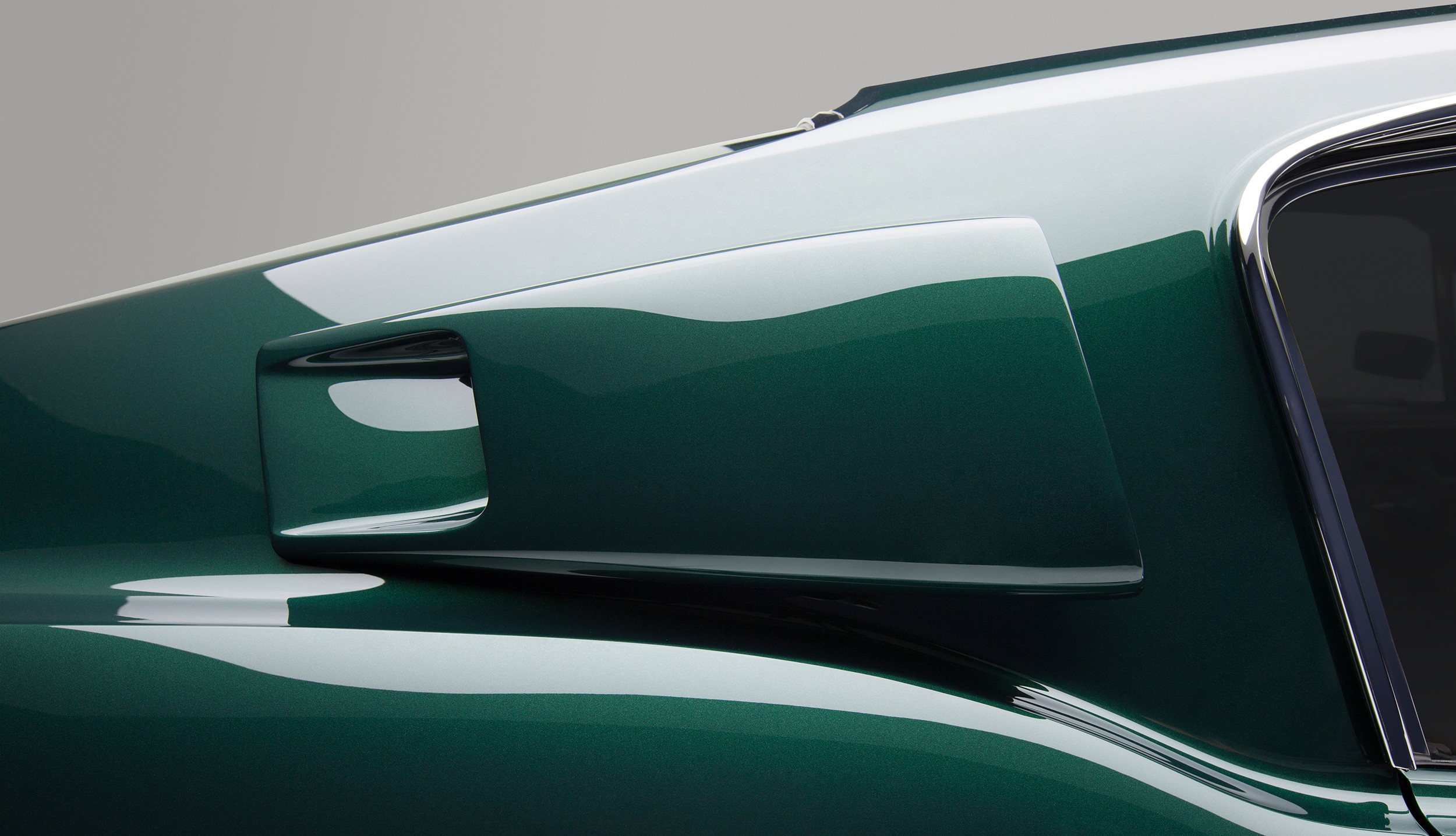

Long hood lines must always run true and consistent edge to edge. Precise is what we do.

Angled gaps fitted to exact tolerance.

Unique Engine Bays that make a statement.

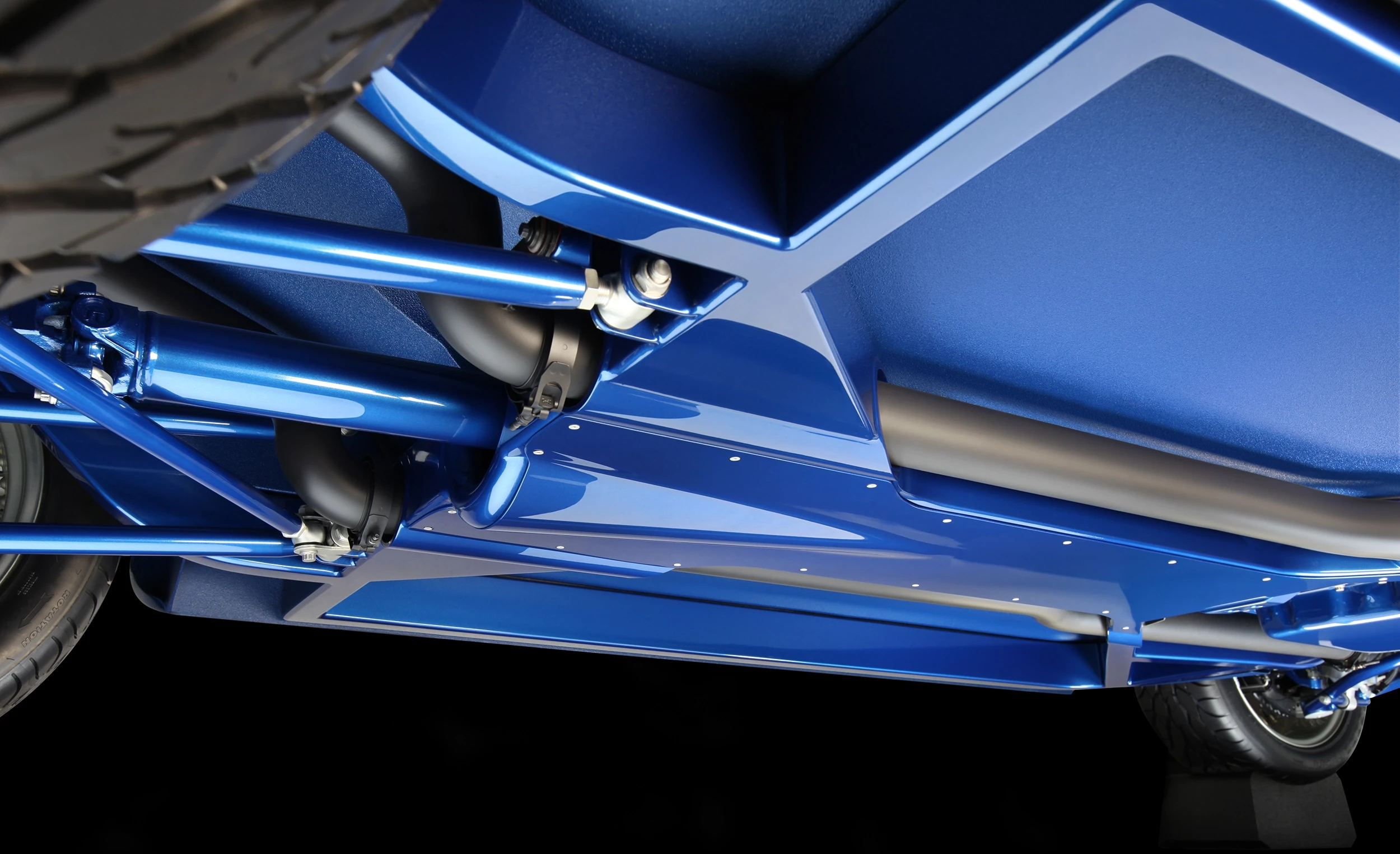

Underside details are beyond sterile belief.

Extremely hard to fit body parts like running boards to fenders receive the same workmanship of consistent 1/16th gaps.

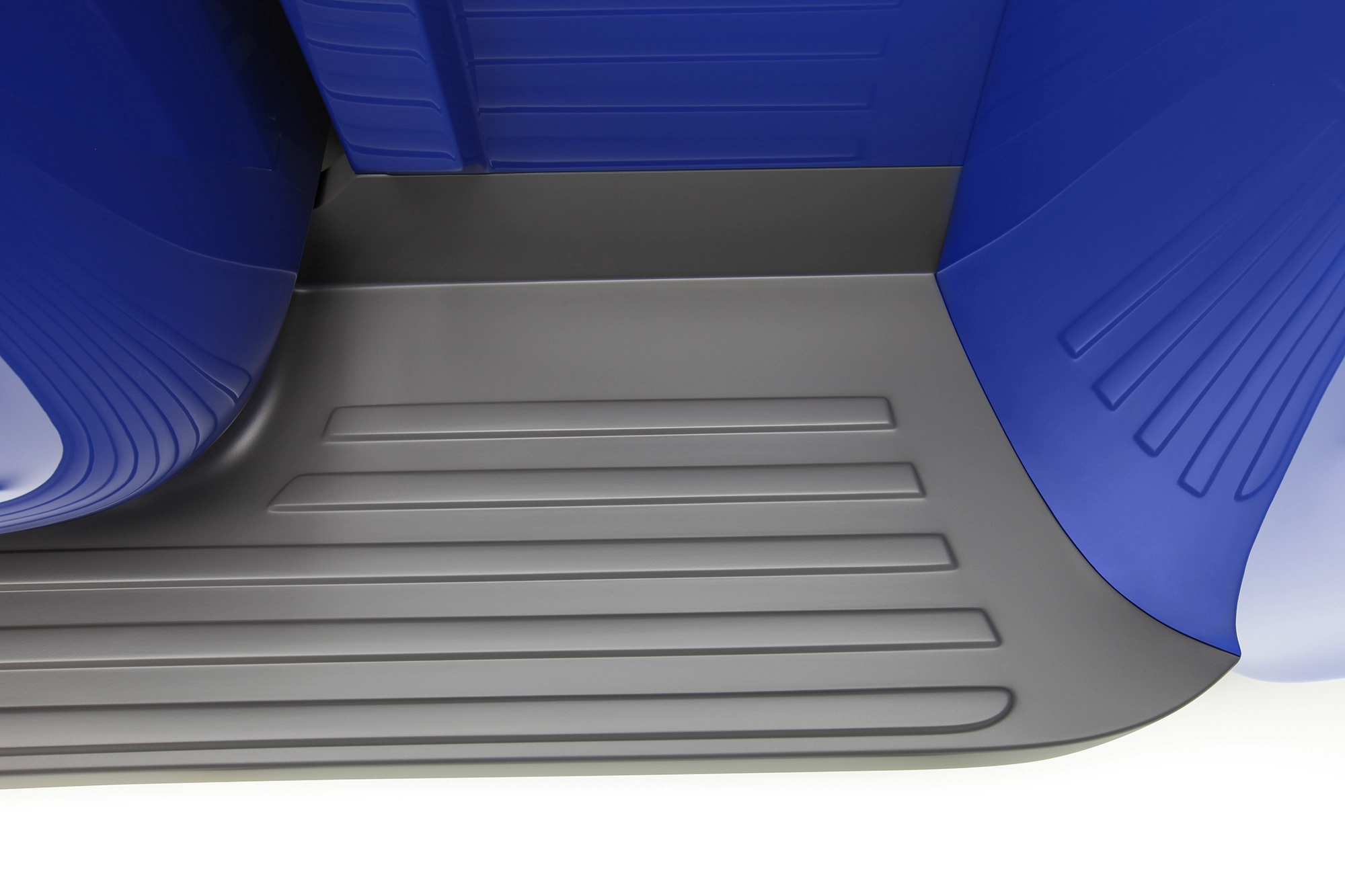

Inside door and jambs are finished to the same level as the exterior paint.

Interior design to personalize your ride.

Custom seats are built to match your projects personalty with beautiful stitch work to finish off the interior.

Seat Backs are gapped and detailed to the same level.

As you look through our website you will see a very organized facility with restoration / restomod techniques rarely seen. Most of our customers will keep their special ride the remainder of their life and then pass it on to a family member that will also enjoy it. When you build with this criteria you build for the long haul and no tiny detail gets left undone. Our team of builders are “ Masters “ in the trade, no beginners here! When you choose us you are getting a professional, well thought out 60 minutes for every hour you pay for.

We specialize in classic car restoration, ensuring every detail is refined.

Our facility speaks for itself with Individual shops for each phase including Body/Fabrication, Block Sanding, Media Blast, Mechanical, Undercoat / Paint Strip, Upholstery, Wood, Paint / Polish and Final Assembly Shops. Each shop contains the proper tools and talent of each member to keep the process running smoothly. Our indoor blasting shop enables us to media blast entire bodies and frames including large parts 365 days a year rain or shine, Heated Dip tanks for grease and rust removal provide maximum efficiency during the initial clean up phase. We take pride in the detailing and assembly of classic cars, ensuring every part fits perfectly. Our expertise extends to customizing Hot Rods, making each one unique. We also build muscle cars, including Mustang, Corvette, Chevelle, and Firebird to name a few. Our experience with building street rods ensures top-notch quality. We handle truck restoration and customization with the same level of care. Proper paint preparation is crucial, and we excel in this process.

Most important, “We keep our Word” to our Customers as we document and provide each step of the process with photos, written logs and addendums on any custom changes to prove our integrity. We make no profit on any parts, we simply pass on any discounts to you. We create custom cars that reflect your vision and our craftsmanship. Envision the finished product in your mind's eye, and we will bring it to life. Investing money in a restomod/restoration is a significant decision, and we take it very serious.

Our finished product is something to behold as we build to satisfy the most critical eye with longevity just as important. Contact us today to get your machine rolling down the road in style.

Our system has been in place since 1957. We have over 35,000 square foot in 13 separate buildings equipped with all of the necessary tools to perform first class work.

At Jeff Lilly Restoration we perform all of the above to the highest level. If your project deserves this treatment please call us to discuss the details. If you have any particular questions, contact us at 210-695-5151 and we will be glad to answer them. Finished Cars and Trucks including our techniques have been published 100’s of times in all major magazines and publications. We appreciate your trust in us and look forward to building your dream!

Sincerely Jeff Lilly