Burl Wood

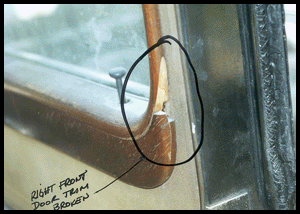

Often we have to repair existing wood that is irreplaceable, such as this Burl wood on a 1939 Caddy Limo. Notice the chunk missing from the interior glass garnish molding!

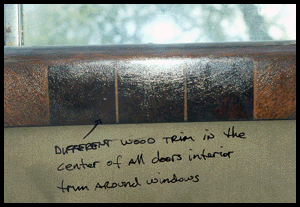

The original burl wood needs a lot of work. It shows signs of flaking and clear exfoliation.

Checked and weathered.

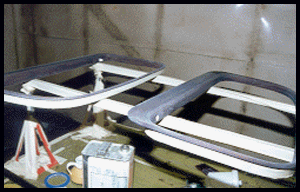

We start by removing all of The window fuzzies and overall dis-assembly of any thing not wood related.

Cleaning out countersunk screw attaching holes is easy with the correct tools and slow rpm.

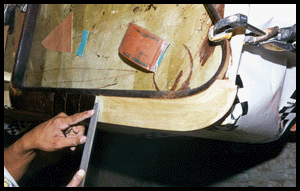

We located and purchased the correct Burl wood veneer and are fitting a template to be cut to size.

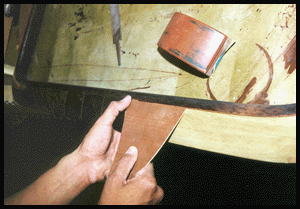

Using the band saw to trim out the initial template, we will then sand the edges by hand for the ultimate fit!

We hand file then sand it to fit in place like a precise jig saw puzzle!

The next step is to fit the smaller and different color section the same as above.

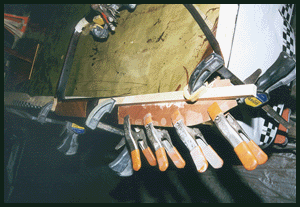

After fitting all panels we glue them in place with lots of clamps "extra hands."

Hand sand every thing level and to an exact tolerance!

Smooth all pieces so they flow together at the same height etc.

We are now ready to clear. We prep the surface then apply Duratech 800A sealer for adhesion then three coats of Crystal Clear.

After a minimum 4 hours we then sand the clear with 180 grit then clear again 4 coats and re sand with 400 and clear 4 more coats. Then we sand 600-800-1000-1200-1500 and polish to a mirror finish.