Bucket Seat

On custom seats or factory foam that is not adequate we glue and add foam where it is necessary to support the outer materials for both quality and longevity. Here Ray is custom contouring foam to exact tolerance with an 1800 rpm hand grinder. Like anything the foundation is what really makes the difference.

Final fit of all vinyl templates. We are pleased with the style and our Customer gives us the thumbs up to proceed.

Senco stapler is used to pull down and hold all materials from the back side such as door panels.

We always check fit for quality control, Looks good !

Our vinyl templates have been pre fitted, removed and we are now ready to cut some cow!

We lay out the templates on top of the new leather and start the cuts. We primarily use Garret leather for all of our hides because they offer some of the best in Italian, German, Asian and American cow hides. Grains will vary depending on what part of the world they are from.

Ray applies glue to the back of the hides and then attaches a thin 1/4 inch foam to the back side before final trim and stitch.

Multiple contours and many angles are the hardest thing for a trimmer to overcome. The results are evident on this close up of Rays work, AWESOME is the only way to explain it ! ! !

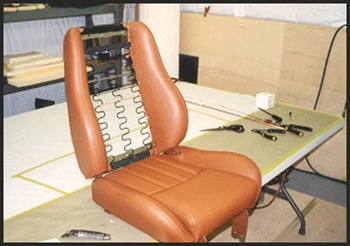

The custom seat is looking good as each section is fitted to the highest tolerance.

The custom seat is looking good!

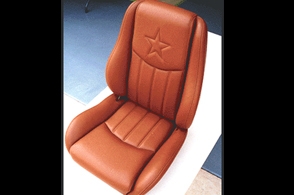

The finished product speaks for it's self. Note, the Customers Choice of Stars for his home in The Lone Star State!

To keep the seats protected before they are installed we completely wrap each seat with plastic and install them into foam supported "no scuff boxes".

Upholstered seats packed safely away until installation day!