Misc

When fitting expensive parts that are cosmetically pleasing to the eye we have to protect them while we install them on to your project. We use 3M tape to achieve this. This tape is easily removed when final assembly takes place.

When parts are detailed and ready to final assemble to each project we wrap them for dust and scratch protection. When each and every part is ready for assembly to your project it goes to together quick/fast and efficient.

Body mounts on a project are critical when it comes to full frame vehicles. Different thicknesses to achieve the ultimate body gaps are vital and they must be put back exactly during the final body to frame drop. We bag each individual one with location to keep this order and eliminate any mistake!!!

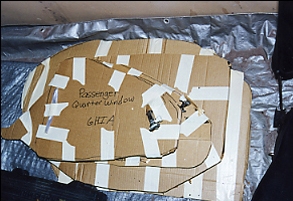

Glass removal and storage is very important when dealing with rare and exotic vehicles. The cardboard "Sandwhich" is the best system for a no problem insured future.

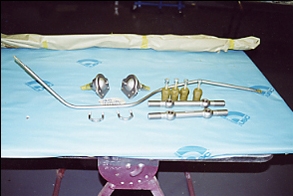

Another important technique is rebuilding door hinges. Being sure to match each hinge for upper, lower, left and right with out mismatching is a must. Keeping them labled during the clean up and rebuild process is critical. The brass/bronze bushings must be matched to the pins.

Details make the difference and these brake assemblies make the mark. You will never be able to see them once installed but just knowing it is right with complete photos proving the work has been done sets your mind at ease. Every time you walk out in to your garage you will know, that you know, that you know that we built it right for you to enjoy the rest of your life and on to your heirs for their enjoyment also!!!

Same here we see the ball joints, control arm shafts etc restored and ready for assembly.

On full restorations every nut bolt and clip has been gone over, bagged, tagged ready to go!

Like an assembly line we get them all ready to go. All of our projects go together quick and smooth like a fine tuned instrument because our system works!!!

These control arms are ready to be installed on a concours project.

When dealing with concours projects we often have to paint original I.D. numbers and markings on parts such as driveshafts and other suspension and frame pieces.

As seen up side down markings were common on parts such as this shaft. Using stencils and paint daubs we do it all.

During dis assembly each project will have old gasoline in their tanks which needs to be removed and disposed of properly. We use a fuel pump mounted to a stand and simply attach it to the fuel line at the motor and drain the tank empty.