Bumper Prep

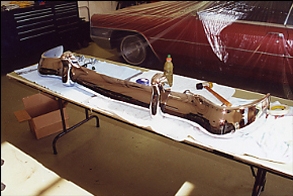

The fit and finish of a bumper is a vital part of any project and we address it for the best results possible. We first remove all chrome, nickel and copper down to the base steel then fit them for correct gap and alignment to the body. At this point we hammer out any dents then file and sand to 320 grit. The last steps are to copper plate then do a light sanding and polish to a brilliant luster before the nickel and chrome is applied for show stopping results.

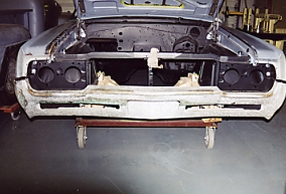

Fitting the gaps is just as important

Hammer and dolly

Sand paper grits are successive to get results.

File the high spots down.

We use flat files and curved files.

Bull nose for those hard to reach areas.

Then comes the hand sanding to refine and remove file scratches.

Power sanders are used to remove scratches where we can.

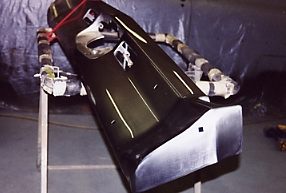

Small areas taken out, as seen factory copper is still on some areas.

Long board files help true up the surface.

Wet her down to site and inspect and mark any flaws left.

Round bumpers take extra work.

The radius is actually easier to work then a flat bumper.

Welding edges and grinding to improve fit is mandatory.

Gaps are big and require welding.

Tape marking and filing for better fit.

The results are show stopping.