Body Gaps

1

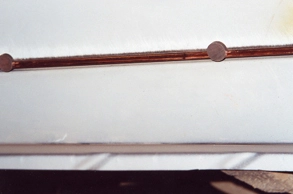

On every projects body we encounter panel gaps that are way off from our required 3/16 fit. Consistency is the name of the game when building top quality vehicles as this makes the difference between a production job and our show stopping results. As seen on this GTX door we have added two 1/8 steel rods to achieve our desired 3/16 gap. Note the small magnets holding them in place to allow for tack welding.

2

A different view!

3

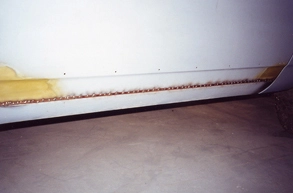

Long panels are best done with a continuous rod. We weld at 1/2 inch increments to ensure that NO warping takes place. Then we grind all welds smooth and "voila" beautiful gaps.