Trim Prep

1

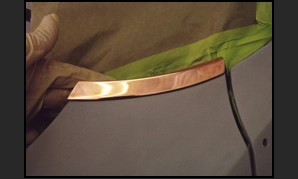

During the blocking stage all Trim parts are stripped of chrome, nickel and copper to bare metal, we then straighten, sand, file and re-copper plate them. They are then refitted one last time. This die cast piece is ready to fit and trim.

2

Nat is using 80 grit to file a tiny amount of copper/base metal off before we chrome plate. This has to be done in the block sanding shop during the course of the blocking phase. A beautiful trim fitted car/truck makes all the difference in a piece of art!