Misc Fabrication

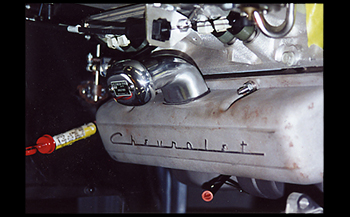

Original 57 Chevrolet valve covers with trick combination breather- oil filler horns installed finished off this engine nicely.

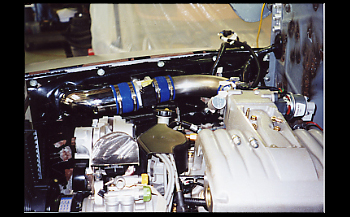

Fuel injection plenum fresh air tubing exits out the side of the inner fender apron.

Another look shows the winding tube equipped with urethane connectors to allow engine movement during acceleration etc.

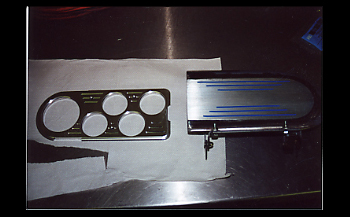

Billet parts machined on the mill are a regular part of our building process. As seen we have taped off the glove box with a symmetrical matching design and we are ready to cut the grooves with a 1/8 carbide bit on the Milling machine!

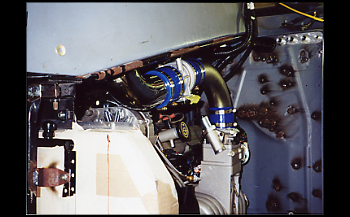

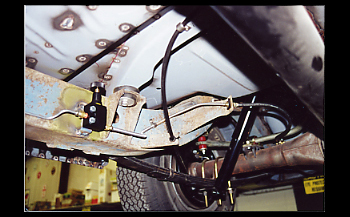

During brake line fabrication we often install adjustable proportioning valves to assure accuracy in front to rear fluid pressure on custom disc brake systems.

To finish off the valve we also installed a stainless shield to protect the unit from heat off the exhaust system thus eliminating any possible problems!

This TVR fiberglass one piece front end needed much help in the area of reinforcement. As seen we are fabricating steel bracing which will be epoxy glued to the back side for optimum no flex durability.

We incorporated a sub woofer speaker system with a relief cut to achieve a hiding place for this bottle jack which can raise the vehicle just enough to change a flat.

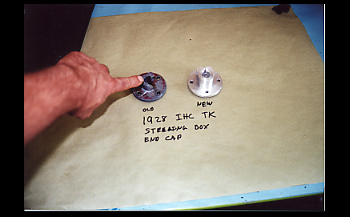

We often machine replacement parts from special grades of aluminum which machine easily but are stronger than the original cast steel pieces.

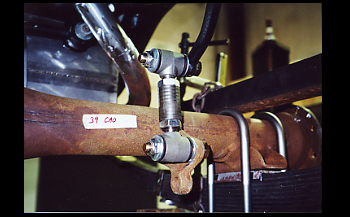

Suspension parts like this steel rod link for a 39 Caddy Limo was built using urethane bushings.

A double proportioning valve with total adjust ability comes in handy when trying to stop heavy 4,000 to 7,000 lb. vehicles.

This removable gas filter is stationed where access is best on this particular vehicle.

Test fitting components is essential when installing many items in the same area. Here we have a new steering column, shifter, bucket seat and drink holder which all have to look good and work together without Interference. Pre-Planning has achieved this and more.