Hood Hinge Tweak

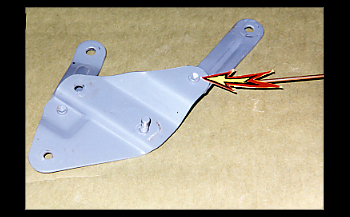

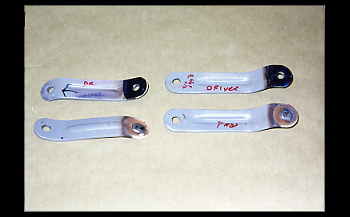

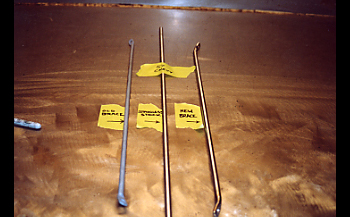

Antique and Classic vehicles pose many challenges while customizing and restoring their components and hood hinges are no exception to the rule. As seen a typical set of 1930 thru 50s style hinges with rivets for pivot points have the usual busted pieces as they were weak and not very suited to performance. We will start by removing the old bolts and welding up the distorted holes and drilling to our desired stud size.

Hinges are hardened steel so when any welding is performed they need to cool in sand as this will retain their case hardened state. As seen the old wallered out holes were welded up solid one side at a time.

One set has been re drilled in the clausing drill press to accept our new shouldered studs.

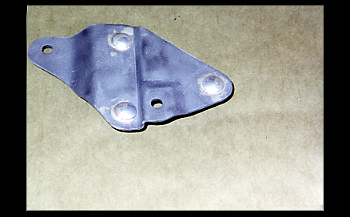

We will now weld our new bolt-studs in the main hinge plate using silver solder. This was performed on the cap head side as well as a hardened washer on the inside which will support a flat bearing.

When you are trying to keep the weld bead down to a minimum, silver solder works great.

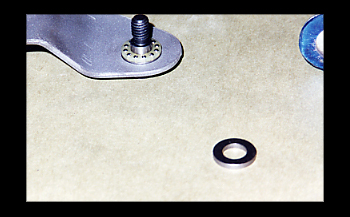

Here we have a thrust-flat bearing which will be sandwiched between two hardened flat washers.

Assembled they will allow the hood to open and close easily.

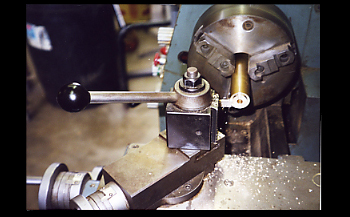

We went to the lathe and machined some nice looking domed supports that are attached with an allen head bolt.

Installed they support the bearing assembly well and look good to boot.

On Custom cars we often upgrade areas the factory did not give proper attention too. This Classic Chevy hood was stiffened with an X brace to help it open and close consistently to eliminate paint chipping problems that these cars were noted for. Fabricated items can make a difference in quality and the longevity of any build.

Fabricated hood supports!

Fabricated hood supports!

Fabricated hood supports!