Brake Pedal

Often we have to fabricate brake/clutch pedals to fit in different vehicles. Height and angle are important when building for comfort and safety. Things to consider are being able to lift your foot from the gas pedal to brake pad quickly and having the gas pedal, brake pedal and if standard shift the clutch pedal spaced so there are no interference problems based on the customers foot size. A size 8 shoe compared to 14 and leg length from hips will change the way we build a pedal assembly.

We started by mocking up templates then fitting by actually sitting in the seat of choice to check for correct size. As seen we are cutting 1/2 inch steel plate on the band saw to make our pedals from scratch. Notice the hole drilled for the pivot shaft. this must be at the precise location for optimum pedal swing geometry.

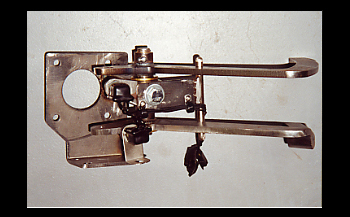

This under the floor unit shows the assembly including pedals, arms, safety stops. neutral safety switch etc. This particular unit is very compact to allow clearance for other components near the frame and exhaust.

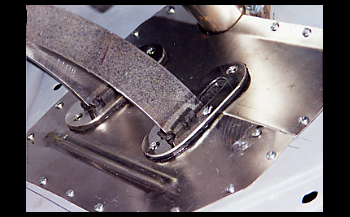

Custom brushes were made to keep dust and dirt from entering the interior. we also made stainless retainers to hold the brushes in place. In addition custom sheetmetal work was installed as an access plate to remove if necessary.

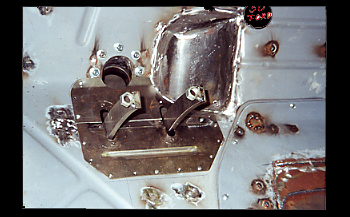

Correct spacing between gas, brake and clutch pedals is vital when you have to make a split decision to stop your special project. A strong but easy way to adjust the spacing is standard nuts welded to the pedal arms to make this happen.

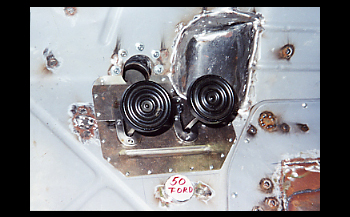

As seen there is ample spacing and the customers foot comfort is optimum with these round pads installed and ready for action.