Block Sanding

Every conceivable shape and size you can imagine is needed to obtain optimum results on all the different body shapes and contours of Super Rods. Shown here are 53 and there are 27 more not pictured that we use for color sanding paint before polishing. Single and double wide, short, medium, long, extra long, round, convex, concave, small, medium and large diameter foams, hard rubber, vinyl backed, levels for straight edges etc You can purchase some blocks from 3M, Motor Guard, Hutchins, Eastwood etc others you will need to fabricate on your own.

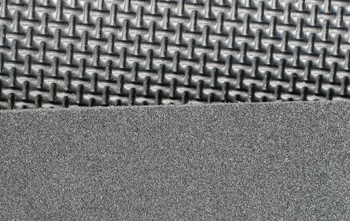

When building your own blocks we have found that Rubatex Rubber is the best choice and it comes in crows feet or smooth. On the sanding blocks that you are going to do 40 to 80 grit work, the adhesive from the paper will tend to release on to the rubber if left on too many hours. On the smooth rubber the glue residue is easier to clean off using thinner and a scuff pad or other solvent between rounds of use. It is always best to remove the sand paper on your blocks at the end of the day for less maintenance and cleanup.

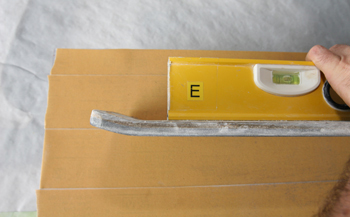

As seen at the black arrow this block has been tweaked on the ends like a bob sled if you will. This keeps the ends from digging in thus eliminating dips from the surface. On do this on all blocks 13 inches or longer. We heat the Lexan with infrared lamps and using a jig we bend the ends and allow to cool. This eliminates any distortion.

Iron sharpens iron as the wise man said. In order to get the results you will have to maintain your blocks and sharpen them on a regular basis. This special "Big Block" is used for such. We run our blocks on this perfect surface to true up all the lexan surfaces before the rubber has been applied and after the rubber is applied we do it again. We also use it to keep the rubber in perfect condition.

Shannon Lilly flips the monster over and you can see what we use. Qty of three, two foot perfect surface levels mounted to 1/2 thick lexan for a true surface to maintain our blocks including the double wide and longest blocks we have. In general 24 inch long blocks are enough to do any surface. This is kind of like the Electric Guitar of block sanding.

The 3M gold stikit paper is the choice to use when sanding primers and fillers. 80 to 500 grit while refining and sculpting. When doing body filler work 3M 40 Board Files # 2231 only come in 17 inch strips.

During body work the use of a straight edge is vital.. It does not matter if the panel is concave/dipped or convex/rounded and/or flat as the distance between the panel and the straight edge on the ends or in the center tells you what you have to work with. In general if you can taper off a dip or concave in a 13 inch distance it will look so gradual that no low spot will be detected. If you have less space then that, it takes some special combing out methods. A convex or rounded area like most fat fendered 30's 40's cars are easier to make look perfect.

With 51 years of blocking experience Bill Lilly qualifies as an authority on the subject. Here he demonstrates one of the flex blocks, notice how easy this block flexes. Two fingers on each end allows ample pressure to get it moving. This block was made from two 3M yellow hand blocks on each end and an 18 inch long piece of 1/8th thick lexan double wide for two sheets of stick it paper. Rubatex rubber was applied with contact cement.

This flex block can be used in a myriad of places but roofs or sloping areas where you want as much contact to the surface as you can get is most important. With the thin 1/8th lexan it is best suited when doing 180-400 grit work like primer blocking.

Bill grabs a round foam block backed by an acrylic rod. You can buy these from body shop supply places or you can make your own from quality pipe insulation foam from Home Depot or Lowes

The concave section where the roof meets the qter panel on a lot of bodies is where this foam block shines. As seen it fits perfectly on this Big Brother Vette.

Another angle shows the rotation needed to achieve the results "black arrows". Twist your fingers in this direction while moving your arms back and forth on the panels, 18-24 inch long strokes. Everything is done in criss cross patterns. The difference is how long the stroke is and how tight the criss cross is done.

These duro blocks are a tiny open cell rubber material. It "gives" a little bit meaning it tends to move with the panel. As seen Bill is using it against the taillight panel on this Vette as it fits nicely. It works well in all grits from 40 to 2500 color sand work. We cut them to different lengths in order to fit them to our panels. We also round the edges a bit to keep them from digging in.

When perfecting gaps we use small metal spreaders 1 to 2 inches wide as seen. Too wide and it tends to dig on the ends as you are working a gap. Too narrow and it does not keep a straight line. These two sizes work best. Simply wrap the stick-it sand paper around it as needed. Always work panel to panel never work a body panel off a car separate from each other or your quality will suffer.

This foam block works good when going from a high to a low section. We removed the rods which stiffened it too much in our opinion " black arrow" These ran through the length of it. We then sliced the foam top, half way down to make it flex side ways and front to back like a "centipede" if you will. Eastwood sells a model like this one but they need to be modified for optimum results much like what we did to this one.

These shapes run in to each other in the center of the door making this a very hard to perfect valley area. We use PVC available from Depot or Lowes and simply cut it to our desired lengths. We then roll contact cement on before applying the rubatex rubber to the surface permanently. The PVC tubing is perfectly straight and makes a very durable light weight block. Because of the two shapes a twisting motion is mandatory as you stroke back and forth stopping where the top and bottom of the cove meet together to keep from digging in a valley that will be seen.

Strange shapes like louvers require many techniques. We fabricate grooved blocks cut from 1/8th 3/16th and 1/4 inch lexan. Notice the grooves are cut some what larger then the louvers them selves to give some motion in order to gradually taper the panel in to the louver for that sweet no dip look.

Many square shapes can be cut from the open cell Durablock rubber to fit a section. As with this inside panel we needed to finish it off for no flaws. We chose a piece thick enough for our fingers to hold it steady yet thin enough to fit inside and clear the overhang.

1/2 inch pvc makes a great block with a glued on handle to grab while blocking. This works great for tight areas like where the spear drops off in to the flat area of this hood.

Nat Ramirez shows us a double wide adjustable block we fabricated. Using an adjustable lead file we built this block to use on panels requiring heavy duty blocking. Just twist your fingers till your desired fit against the panel you are working and your ready to "block and roll". Nat is the best blocker I have ever seen and can remove any ripple or imperfection on any body style thrown his way.

As seen Nat adjusted the block to fit this rounded contour on a 50 Ford Custom truck. As much surface contact as you can get is best with the ends just off the panel.

The rounded corners of this tail gate show a lexan mini block made specifically for this panel to get the results needed. As seen the tail gate shows its reflection stuff revealing the proper tool was used. You can purchase lexan at a plastic supply house in any desired thickness. Simply cut it with a jig or band saw and then file the edges burr free. Drill, taper, screw to a hard level or straight block then add rubber and you are ready.

Up inside the bed we used an angled block we fabbed to fit in the corners. This enables you to block with out digging a rut or valley when trying to match the inside edges.

Large panels like this convex door require a simple flat block 18 inches long. We have 11 inches of contact in the middle. This type of shape is gravy or easy to perfect. Notice the hand and fingers. Just enough pressure that you do not push against the panel and your hands will not become fatigued easily. The vehicle should not rock and or move at all or you are being to aggressive and pushing which will tend to dip the surface.

The holding of a block is equally important for the criss cross pattern needed to achieve the best results " see arrows " Nat is in position with the "Body mans crouch" balanced and ready. We also use rolling office chairs while working some panels if access is available to the panel. In this case the running board would not allow him to sit in a chair while blocking.

Bill uses a single wide or typical width block to slice the top sections in to submission. Notice the handle is an aluminum level. The level makes a perfect surface to screw the lexan to and then apply the rubatex rubber. You have a dead on straight surface with this fabricated block.

This Super Rod Firebird received the "Durablock" treatment with the 9 inch block to sculpt the hood scoops to the flat section for a no ripple transition. A very strange and unusual shape to deal with. "Red Line Shows It"

When coming up to fender beads we slice the lexan on an angle which keeps the block running close to the edge compared to a square edge which would dig in to it. This 65 Corvair fender shows a great example of such. Most of the fenders that have a wheel lip 1954 on up are actually pressed in above the lip and will look dipped in this area because of the pressure from the mold process when making the fender. This is the way we have been able to remove the factory dips

A different fender lip or gradual flare style used on a lot of GM cars like Camaros require a C- Block. This was cut specifically for this type of shape. It removes dips and allows you to get in to the contours as close as possible.

This skinny open level does a great job with 1/8 thick rubber, on drip rail inside edges. This is an area that needs a special block like this in order to get close inside the drip edge for a ripple free surface.

We finish it off with 1/8th thick lexan. Masking tape was applied on the block as a mini cushion before stikit sand paper.

When all is said and done you want a ripple free surface with panel to panel fit dead on like the side of this Corvair Custom Rod. Lookin good!