69 Camaro Rear Mockup #1

Many people will agree that the 69 Camaro body is a very nice design from GM as it is accepted by the Chevy faithful as one of the most beloved cars ever built with a Bow-Tie emblem. In my opinion every car has some areas of the body that were not designed as well as other areas and that is what we are looking to change. Leave the beauty and take out the ugly parts.

Personally I never cared for the way GM ended the the body lines at the back, They stopped them abruptly and that is one of the main things we are wanting to change. As you watch our steps try and see it through our eyes before you make a judgment call.

In order to start the process I always do a chip board / wire reinforced mock up. One of the first things I want to change are the " too short qter panels " so I start with extending the rear qter with 6 inches of material. I prefer to do " Quick" mockups to see it in true 4D. This way a client can actually see the size and shape to know for sure. The problem with a drawing is that it is not three dimensional and often you can not build what was drawn out, it works on paper but not in real life.

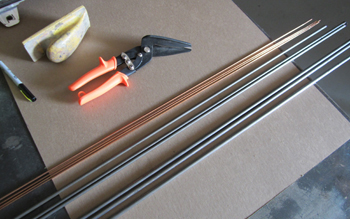

Tools of the trade. I use basic stuff like masking tape, chip board, 1/16th 1/8th 3/16 and 1/4 inch wire to do most of my mockups also known as " wire forming" to shape my designs. Note the long nose snips, they cut chip board in straight lines and curves precisely and very easily.

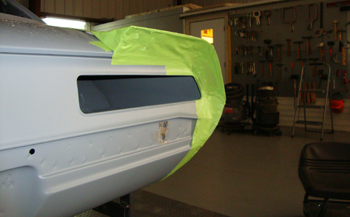

The chip board and tape will always look a little bulky compared to the actual metal forming process but I like to use it for fast mockups to be sure we are headed in the right direction to keep the costs down and show the client some ideas he can trust to make a wise decision. Digital pictures emailed to the client for a yes or no and you are back on the path to getting it accepted.

Inside angle shows a deep set spoiler and around 3.5 inch longer at the top compared to the original qter panel.

Another angle shows a bit of a of a Le-Mans style with a swooping rear section. The glowing green tape makes it look bigger then it really is and we take that in to consideration when designing. Using clay mock ups and wood bucks uses a tremendous amount of time compared to our method. Hey the bottom line is you have to be efficient as possible and hit the ground running at all times. Just a quick idea on the rear bumper is drawn with a jumbo marker as we kick it around to decide if we like it and or if tweaking is needed.

Angle bumper idea is ok but not as nice as squared off. Our client has seen the mock up and likes the idea so its wire and metal time, lets see how its done. Go to Metal work #1 check it out !