50 Ford Truck - Head Opening Trim

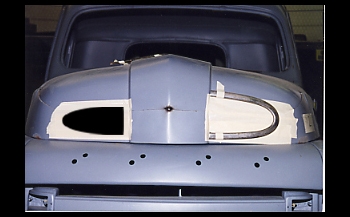

We will be building trim for the hood openings on this 50 Ford Truck. The hood was shaved 3 inches lower than stock and will no longer accept the original stainless parts. As seen on the right the original trim is huge and gaudy looking. On the left it shows a smaller comparison.

To check size for the customers approval we mocked up a few pieces in thin gauge steel and covered them with tape for visual purposes.

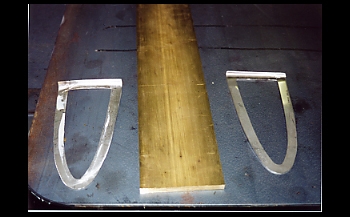

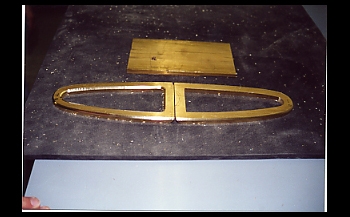

The customer was pleased with the new size so we purchased some brass stock 1/2 inch thick to start our new project. Brass works well because it is easy to machine and tweak. Brass also accepts copper plating well from an adhesion standpoint and copper accepts Nickel and Chrome very well so you have a natural metal plating match.

Kenny starts by using a saw with a metal blade and rough cuts out the pieces.

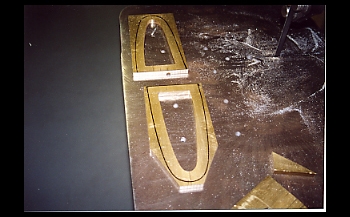

Ken then takes the router with equipped bit and cuts out the centers. The soft brass trims easily with this tool.

They are roughed out and taking shape as seen. The band saw will be used to trim a bit closer to the lines now that they are smaller and will fit between the band saw blade and its frame.

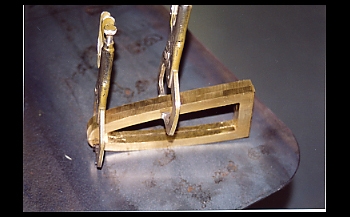

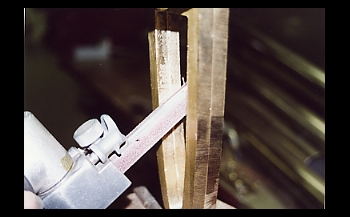

Clamped togeather he will now make each piece identical by filing them simultaneously.

A die grinder with a porting cone grind disc works great to rough it out at first.

The Dyna brade belt sander with 80 grit works out more angles.

He now switches to hand filing for a closer tolerance. The right file with correct teeth per inch is important to keep from loading up when filing soft materials like brass.

The round file works great for all corners.

Filed to a dead set match she is starting to take shape!

50 Ford Truck - Head Opening Trim

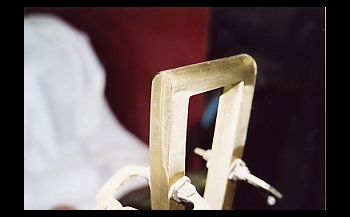

Initial fit to the hood opening shows they need tweaking to match the hoods contour.

Ken taped them up to check the opening size and angle before tweaking.

Before he removed them he marked the back side where the threads will be for attaching to the vehicle. He then clamped them in place and pilot drilled them for future thread tapping.

To take it the next level the router and bit is placed upside down in the table and with two hands on the part a bit more finesse is applied.

Rounded and taking shape she is coming a"round" nicely.

On the left you can see the shape taking place on the inside and outside edges compared to the right one that still needs run through the router.

Ken wraps them in clean cloth and inserts soft jaws in the vice. He then lightly taps the trim parts to fit the hood radius exactly. Ken uses a soft faced dead blow hammer to do the job.

Just like an isontoner glove, the fit is right.

They are about 90% Finished and have been hand sanded a bit with 80 grit. Once the body is in final primer we will finish the fit and start the Copper Nickel and Chrome plating process.

50 Ford Truck - Head Opening Trim