50 Ford Truck - Assembly, Paint & Polish

There are so many areas that need tweaking and the glass is no exception. As seen the "KIT" of laminated glass needed trimming on the edges to fit in the confines of the window channels. This allowed the rubber to sit nicely against the painted surface. Using silicone carbide abrasive and the correct sander we are able to shave down the edges being careful not to create too much heat.

Every one enjoys a nice looking wood bed but the work it takes is more then one "wood" think. Hey you have to laugh a bit to keep your sanity in this business.

On the back side of the wood against the bed side panels we point to where the wood was cut away for clearance of the bolt heads that hold the fenders on to the truck. Small reliefs are cut in to the back side of the wood using a Forister drill bit so that no fasteners are detected.

Once removed you can see all the reliefs it took. On one piece alone!

Quality levels have always been decided on each persons critiquing ability and the effort to build a piece of art to the highest level is always created by Time and Knowledge. Mike puts his arms to the tested Max in polishing the back side of the hood on Ol Yeller.

The tail gate received the same treatment and Nat is the best in the business when it comes to leveling the paint by color sanding.

Every nook and I mean every nook and cranny is what we do so that no matter who critiques it, It will stand tall. Nat polishes the tail gate in and around every curve including the lettering.

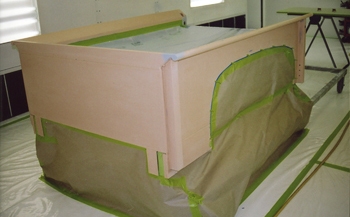

The bed was sprayed separately as were all the panels for the best quality.