1971 Wagon - Bumper Prep

The bumpers were stripped of all the chrome and nickel then aligned to the car.

As seen many pits were in the steel. We metal work and copper plate to fill in these types of imperfections. The copper also provides the adhesion for the nickel and chrome.

As seen the metal work phase is starting to remove the high spots and level the surface.

The dents and most of the pits have been removed, now she is ready for copper.

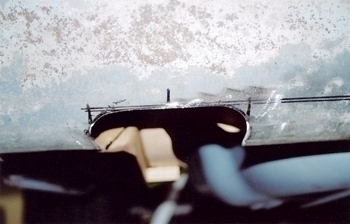

On the rear bumper we also cut out sections for custom exhaust tips to clear.

We then smoothed the cut out by adding an edge to give it a factory look.

The copper plating is done and now it is time to final block sand, then polish the copper before plating.

The bumpers were fitted to the car for precise gapping and dent removal then filed, sanded and hand worked to the maximum on bare steel. They were then acid copper plated for build and refined in 180-320- 400 grit and polished to this point.

The Copper is polished to a mirror finish before they are ready for nickel and final chrome.

With Jeff's "Thumbs up" sign of approval we are ready for the last two phases of plating. For a detailed step by step system go to our build tips page and click on "Chrome Prep".

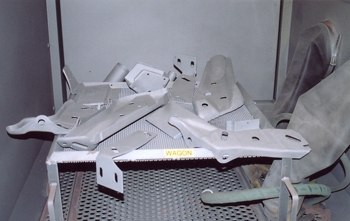

The bumper brackets also get blasted and primed before installation.