1971 Wagon - Bolt Prep

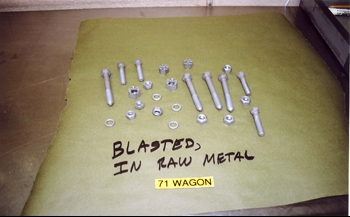

On non stock builds we generally use new fasteners but there is usually an original type of bolt that a MFG made specifically for that model. In those cases we Plate them to look like stainless. They start out with surface rust so we check them for overall condition being sure they will perform.

We then blast with 80 grit alum oxide to take off the rust and then use #13 or 320 grit glass bead for the final media used to give a smooth texture on the base metal to allow the plating to go on as smooth as possible.

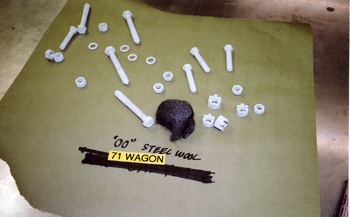

Depending on the size of the fastener we check them on a regular basis for the amount of time needed to plate effectively.

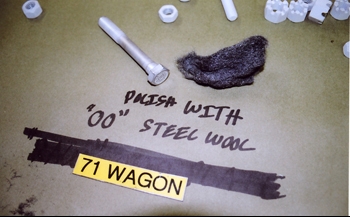

Raw cad plate takes a bit of smoothing, so double ought steel wool is used to finish it off.

As seen, it takes the hard edges off the part. It is now ready to clear coat for protection against acid from human hands.