1966 Mustang - Disassembly Clean Up

As we disassembled the 1966 Mustang we started to uncover past repairs that were done incorrectly including a myriad of rust problems. Hence the name " RUST STANG " is what we will call her until she reaches our requirements of quality. At that point in time her new name will emerge as " PRISTANG" .

The lower grille and headlight brackets are 1 inch above the factory holes so we know some sort of collision has taken place at one time. This is a typical production body shop repair method where there was only so much money the insurance company was going to pay and this is what you get.

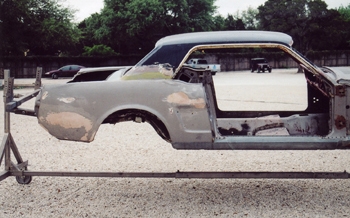

The little Mustang is coming apart.

Bottom of each fender is rotted through on the brackets, we have our work cut out for us on this Mustang restoration project.

The little 289 had Headers installed but the car is being built close to Concours so original cast iron manifolds will be installed.

A production body shop actually welded the front valance on to the fenders. We had to cut it loose.

Typical grease and grime. She is ready for a thorough cleaning. We have it mounted to a body rotator to get full access during stripping etc.

Jack pressure washes it down to reveal more work needing done.

Mega bondo patches are every where. Note the roof is still painted as it was so rough around the drip rails that a new roof will have to be installed.

This side also shows the abuse of bondo.

Some one had attached some sort of weird brackets on the frame for pulling or?

More strange brackets attached that we will remove.

We performed undercoat removal on the panels to clean the Mustang up and also get access to the back sides during dent removal.