1966 Mustang - Mech Rebuild

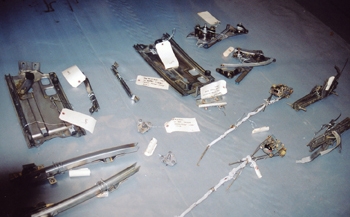

We obviously can not show every part we rebuilt on the little PONY but here is a few items just to give you a glimpse of what it took to put it back to better then new. Every window crank, door track and metal part off the car was dip tanked clean before any rebuilding took place.

New lug studs on every project. We never trust 40 plus year old studs with your families life on the line.

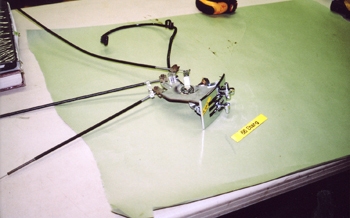

Every switch was rebuilt and detailed to perform like new or better in most cases.

Blasted white metal clean.

Zinc chromate for adhesion.

Cast iron finish and ready to assemble on to the car.

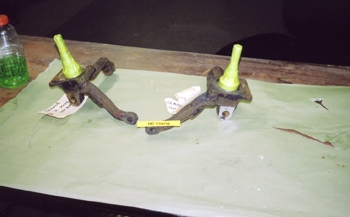

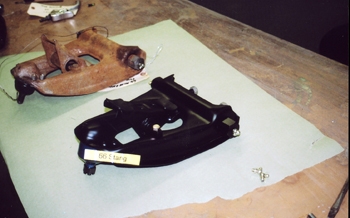

Control arms were stripped, media blasted, rebuilt with new bushings then primed zinc chromate.

Detailed, painted black and cast iron with bare steel where applicable.

Before and after tell the story.

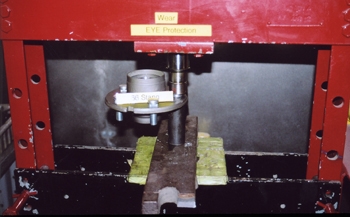

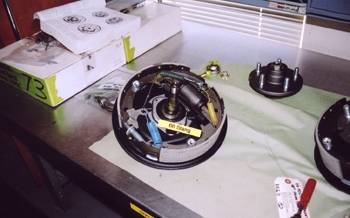

Brake backing plates usually wear out on the flats from friction so we weld, then grind smooth for another 200 K. miles

Welded up and ready to file.

Filed and ready to prep.

Media blast white metal clean.

Zinc chromate primer was applied for Max adhesion between the bare steel and paint

Once assembled you have a beautiful brake system.

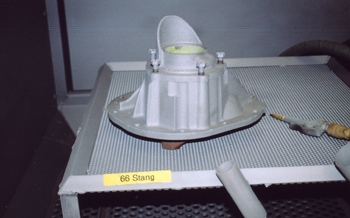

Rear housing gets the same treatment.

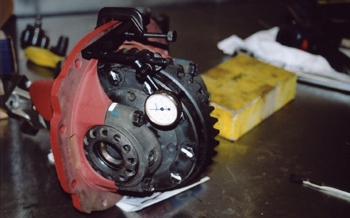

The old center section has seen better days so complete rebuild is needed. New bearings, seals, gears then set the lash so no noise is made.

White metal clean as are all our prep jobs.

Correct shade of red oxide.

Gears set to correct lash with shims for a quiet rear end.

Once completed there is no finer rear end on a Stang.

Steering box also rebuilt completely.

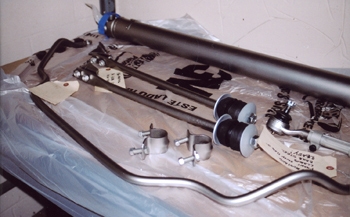

Sway bar drive shaft all done so Max efficiency during final assembly can take place.

Brake pedal assembly done to top specs.

Rebuilt detailed etc.

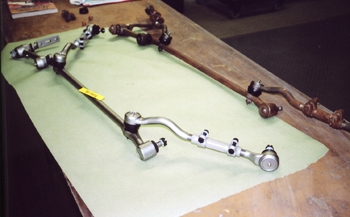

New parts for steering linkage but detailed for longevity and looks.

Before and after tell the story. Need I say more?

Heater boxes rebuilt then detailed better then new. Seals are fabricated when there are none available.

Tested and ready for final assembly in to the Pony now known as " PrisStang".