1966 Mustang - Engine

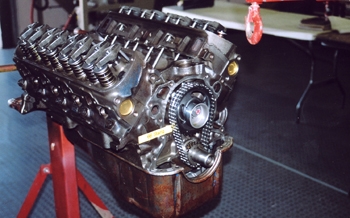

We build all of our engines with the utmost precision for a balanced assembly that will idle smooth and perform at peak horsepower regardless if we are doing a stock 289 or a race motor.

The block is then taped up on all the openings to keep out any debris before our wire wheeling procedures.

We use a variety of tools including every conceivable wire wheel and scuff pad to get the porous cast iron to come clean. This is the only way to get Max adhesion for longevity of the painted surfaces.

Bill does his thing and preps the block.

As seen, extremely clean and ready to wash down with solvent to remove any residues of oil then re mask before priming.

Zinc chromate is then applied. On to the smaller parts of the engine that will also receive color.

The oil pan gets prepped to refine the gasket sealing areas etc.

We must get it straight for perfect no leak sealing. Then we will media blast, prime and install it before painting the engine as an assembly.

Timing chain cover gets media blasted for Max adhesion of paint.

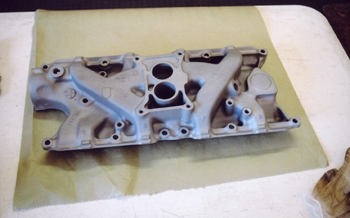

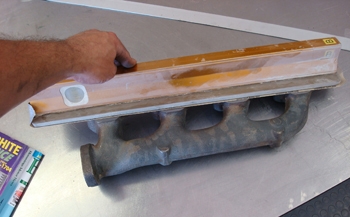

The intake gets the same treatment.

After market A/C is being installed. This customer lives in Texas so this is pretty much a mandatory addition. As seen the " Kit " does not fit well and needs some tweaking. Spacers will be made.

The brackets do not line up so welding up the old holes is needed before re drilling.

The desire is for a straight running drive belt that will not blow off the pulley at high speed. We need to do a bit of tweaking.

On to the grinder we machine the surface of the idler pulley a bit to get her straight and true.

Exhaust manifolds are new but still require some refining.

The grinder makes short work of them with a perfect surface table.

As seen the surface of the end port is barely touching on one corner so a bit more grinding is needed.

A small amount of hand sanding to perfect and we are ready.

Prepped, mask and ready for 3 coats of blue.

All remaining engine parts get the same treatment .

2 coats of blue on the engine.

Wet and glossy is how we do it!

The engine has been painted and assembly is started.

New everything.

Many components.

289 decal is applied for the famous power plant

The air / choke tube was painted with 1200 degree high heat paint.

As it was lowered in to place she started to come alive.

The under side looks good and is coming along nicely.

Date coded plug wires were installed. Details make the difference. Once the engine is tuned and no other rocker arm adjustment are needed we will paint the valve cover bolts at the very end.

Black A/C compressor blends in for a more stock appearance. Most customers want the original look on the exterior with upgrades to make their cruising more enjoyable.