1966 442 - Upholstery

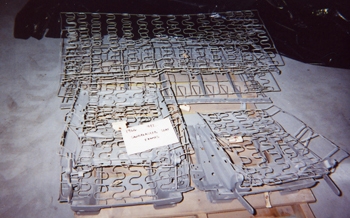

442, yo dude these seats are wasted. We tak'em down all the way. No quick slicks at this shop. Springs are blasted and ready for priming. At that point we add wire rods to stabilize and make the outer edges straight to eliminate any dips in the covers.

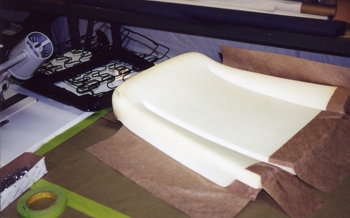

New foam is available for these seats so we purchased them. Problem is they are usually over sized so shaving is needed to get the covers to fit.

As seen rods are standing by to hog ring in place and or be welded where needed.

Coming around and starting to take shape.

Very nice style back in 1966 where you could get your kicks on Route 66.

Rear seat gets the same treatment.

Pack her in a protective box until the car is finished.

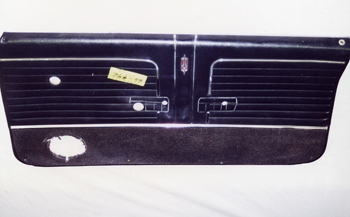

Original door panels have many issues with moldings and clips every where.

Eric punches holes in the new card board stock for mounting the trim.

Ready to attach the trim.

Eric welded new studs on the molding as the factory studs were all rusted out and none available repro.

Once all is drilled and the trim lines up to the matching rear qter panel CV top cover he taps over the studs to hold the trim in place.

Trim is in place and panel is getting close to finish.

All remaining trim was installed after drilling the panel first and pushing over the tabs. Note the tape to protect the polished stainless from scratching while working the panel.

Looking good and ready.

Arm rests need love too.

Steel reinforcements are on the qter covers to back up the panel but they needed re-drilling to make the moldings straight as the factory originally had them crooked.

He drills out the mounting holes for window fuzzies on the rear qter interior panel.

Rear qter panel convertible top mechanism covers are finished also.