63 Galaxie Firewall Transmission

The fire wall must be moved back 4 inches from where the factory had it placed to clear our new engine and other items to be installed. We cut off the side panels Ford had and off we go for more slicing and dicing.

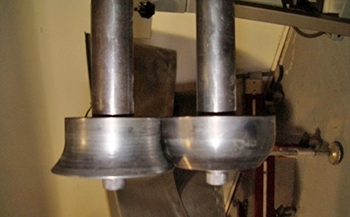

We also cut away the top of the fire wall back to clear the injector stacks and make room for the tubing structure we will install in to the the car for reinforcement.

We placed square tubing on the sides but went with round over the top to allow a smooth transition of the fire wall sheet metal we will be building later.

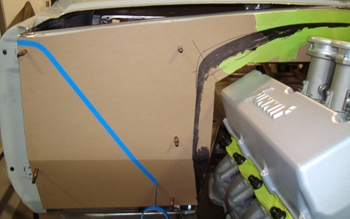

It is time to build the fire wall on the Galaxie now that we know where our engine and other items are set. As usual we do a mock up on chip board until we are satisfied with the look we are after. We colored in the sides in keeping with the valve cover profile and we like it. We also mocked up the inner apron location with blue tape.

Our fire wall is backed up by a tubular reinforced cage to attach components to such as A/C box, brake lines, steering column, dash etc.

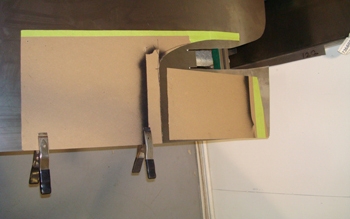

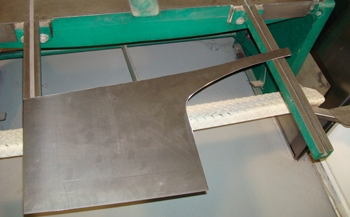

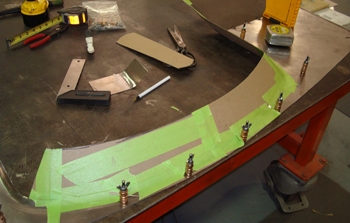

We lay out the fire wall mock up on to some metal and start the process.

Sheared and trimmed. As seen only one half of it was built. We made it this way because it would be flimsy in the center with such a small strip at the top. We built a duplicate piece for the other side and are ready to fit.

We rolled the edges in with a set of dies custom machined for such bends.

Both halves are held in by clecos. We also rounded the edges that curve in toward the back of the motor.

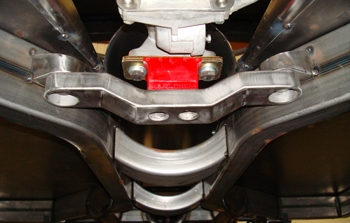

Looking up from the ground you see the angle needed to go behind the engine and complete the back side of the fire wall.

Lou pulled the finished sides back out and mocked up part of the angle toward the back of the engine.

This shot shows a nice angle of the pieces making the contour in and around the back of the engine including the rolled edges we did.

The finished fire wall came out nice as we designed it to complement and or fit the engine with the valve covers we will be using.

The customer wants to retain as much of a stock looking interior as possible of an original 64 XL Galaxie, so we have to make the orig console fit around the larger trans tunnel. We suspended it with a piece of string to get an idea of our options.

The green tape shows the room needed for the trans to be pulled out if/when service is ever needed. This is where the tranny tunnel will be placed.

On both sides of the transmission we fabbed panels to go from the floor up to meet the trans tunnel.

Rear view shows the sides of the floor and trans tunnel where we must join.

A wire is used to mock up and check for the minimum clearance needed to clear the transmission to the bottom of the fire wall we will be making.

We mocked our trans tunnel cover and we have just enough room to make the console fit.

Fire wall interior side is looking good. Come back for more build photos of this Big Motor Ford.

The finished trans tunnel allows the factory console to fit nicely along with the top floor sections that are fitted in to support the foam and carpet.