63 Galaxie Chassis

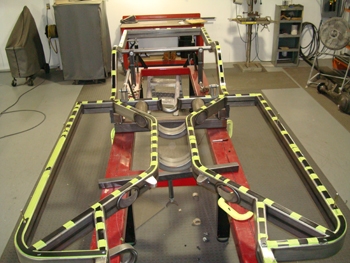

1. The chassis is now ready for the bodies initial fit.

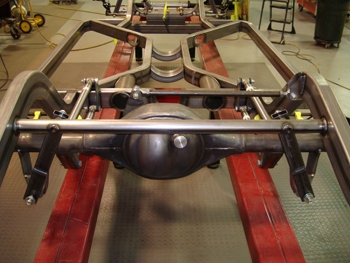

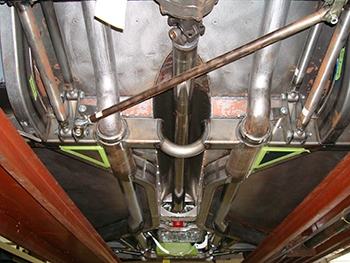

2. Tubular control arms are ready to keep this Ford hooked in on the most demanding turn. Air bags will be installed on this project to slam it if needed.

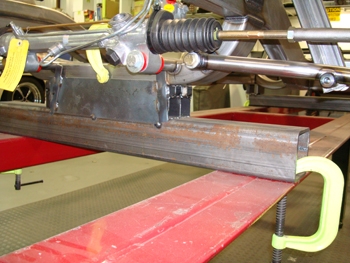

3. The power Rack and Pinion steering system will assist the big car with a tighter radius for quick turn ability.

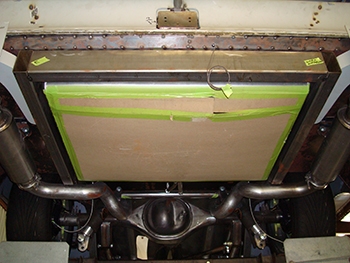

4. Custom Cut outs for 3 inch exhaust to exit are nice.

5. The nine inch Ford rear end awaits axles and center section.

6. We like to clamp every thing in place to keep it all aligned during the body fit. Including angle pieces to keep it from shifting during fabrication etc.

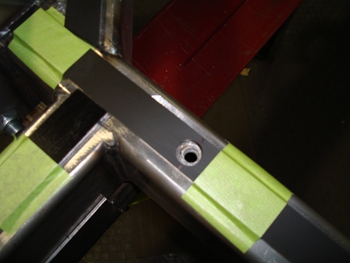

As seen we used continuous neoprene rubber in 1/8th thick by 1 inch wide strips for our body mounts. This enables us to support the floor system we built very thoroughly compared to the usual donut style rubber mounts with separate locations like most full framed cars and trucks. This also eliminates body flex and or misaligned panels that the donut style rubber mounts are often known to create. Keep in mind our custom floor system was designed in house to mount to the frame with no "outriggers" like a typical frame is built. Our frame and floor system not only provides 100 percent contact but is a much cleaner looking frame and floor combination, which also helps during the paint and refinish stage.

Standing back the frame is covered with rubber strips, the green tape is only temporary as we designed the mounts with self adhesive backing to be installed permanently once the body and frame go back together for the last time.