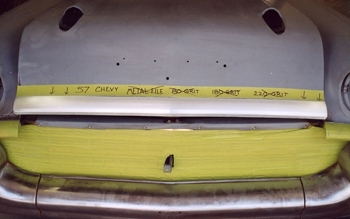

57 Chevy - Refine Trim Fit

A 57 is loaded with trim. As seen we tweaked, fit and shaved to get a great fit.

Gaps between hood and fenders are dead on.

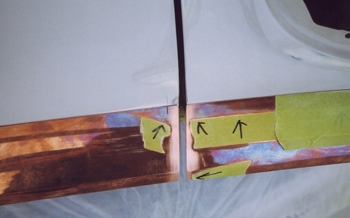

Close up shows working the copper etc on these pot metal/diecast parts.

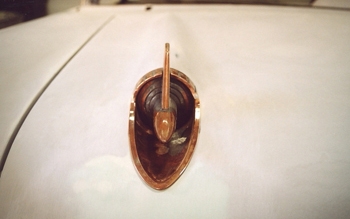

Hood spears are straight and true with razor blade gap.

As seen from the side we fit and sliced to fit exact.

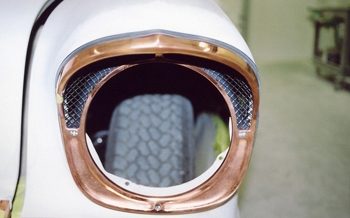

Same goes for the head lamp extensions with or even with out the rubber seal Chevrolet installed them with they fit great.

Having them straight with no twist is vital for a world class car.

Door handles, finger guards etc all tweaked, filed and sanded. We are getting close.

As seen during the block sanding we cut through the copper when removing some ripples from the part so more copper needs to be applied.

Nat has the "HANDS" to achieve world class results. Trained by the best to become the ultimate! And he is.

The mirror to fender sits nice with a razor blade gap also.

Even the A/C dash vent bezels are gone over.

Stainless trim is fitted, cleaned then polished.

The tail fin crown moldings are being upgraded to bolt on studs instead of the factory pop in ones that tend to grab too hard which causes them to push on the paint too much.

Removal of the old push in style stud takes place first.

Welded in threaded studs will allow bolting them in place with just the right amount of draw tension.

All fitted and looking good.