57 Chevy - Rebody

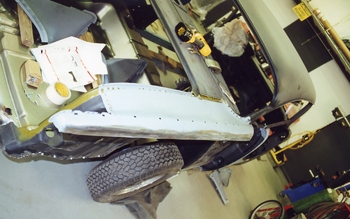

The fenders were gone at the bottom so rust repairs were in order.

As seen we patched it in with a non detectable repair.

Every thing is rusty and gone on this car so a re-body is waiting to be performed. 50 years of undercoat, goo and rust stare us in the face but we never back down from a good fight !

We want to save what we can so clean up and inspection has to take place to see what can be salvaged.

The old trunk had to come out as she was long gone and riddled with holes.

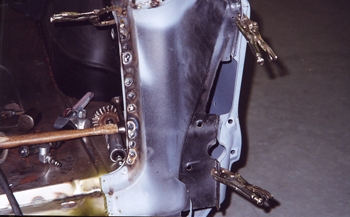

Inner trunk walls have the usual rusted out seams but we can save them by inserting perfectly cut patches with out any one detecting a repair.

De greased, undercoat removed and then media blasted, now we know what we truly have to start with.

Big "Al " blows out the media and begins the task of masking off all the areas needing repair and then priming the good sections.

Hey the dash was salvageable.

The driver side inner structures are some what intact. With some repairs we can get her ready to re-body.

All primed up and ready for body panel fit.

The original trunk floor shock mounts glare at us with memories of the past and better days ahead.

55 thru 57 Metal has to be chosen from the right companies in order to get the best fit. Here the new trunk is being fitted.

Next the inner rocker panel is lined up and checked for square.

Clamped up and waiting

Outer rocker next.

Door striker post outer panel was next in line.

Cross braces were installed using new body mounts and screwed to the inside rockers. We always check the frame first before building a car. This one was checked for square and true and was found to be nice.

Upper qter sections to the left and right of the trunk lid get worked.

Now attached . All these panels are clecoed or self tap screwed in place before any welding is done. Everything has to be aligned and tweaked once over before the final step of welding.

Passenger side floor section goes in next.

The other half of the floor is now installed, as seen hundreds of screws are holding it down tight with spot weld holes next to them on top of the braces.

All looks good so we can weld up the floor.

Although this is not from the factory we build these skeleton wheel house supports to reinforce the qter panels on Classic Chevys during a custom build. That eliminates the wavy qters on 55 to 57s because there is no outer wheel house support attached to the wheel lip on these cars originally. THIS IS THE REMEDY !

All new qters, ready for install.

Rodney checks the door to qter fit and she looks good. A little porta power adjustment before screwing in place.

All lined up and starting to look like a car. But there are more areas to check.

The rear inside tail fins need tweaking to keep them straight up and not leaning inward or outward.

The rear trim was installed including the tail light housings ect

Front sheet metal lines up also. Time to weld up.