57 Chevy - Initial Trim Fit

All of the outer trim is pre fit for gap to body contact.

NOS, nice used, a bit of reproduction and we have a nice car.

These pieces are the hardest thing to find nice on a 57 but Jeff was determined to find a nice set. So he searched the world over and thought he found true parts, he found some others and whoops they were ON! Roof to qter pillar moldings.

NOS or new original trim, we got what we could but it is getting harder all the time to find. "Like Pulling Dinosaur Teeth"

Flippers, door window trim etc.

Glass molding trim clips were pre fit.

The glass is also pre fit to be sure of no surprises during final assembly.

All trim is gathered and accounted for before we start to remove dents and polish. For more detailed information search amazon.com or ebay for Jeffs best selling book " How To Restore Automotive Trim"

The difference between a stock and tweaked one is notable.

We will duplicate them both the same to match side to side. As seen we will trim the excess edge off to give it a nicer appearance and fit the car better.

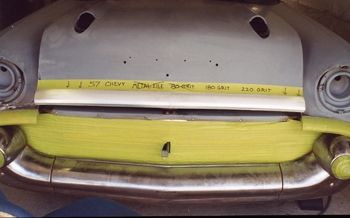

Hood bar, fender extentions all lined up and ready for some prep.

As seen the chrome, nickel and copper have been stripped. We ran a block over the surface so we could see where our highs and low were.

The die cast hood trim is a soft metal so we blocked it out using 80 grit 180 then finally 220 to its current state. It is now time to re plate with copper to get it ready for the nickel and chrome.