57 Chevy - Final Pot Metal

Eric checks the copper plated A/C vent for gap to body and she needs some work.

As seen she has a large gap and needs final fitted.

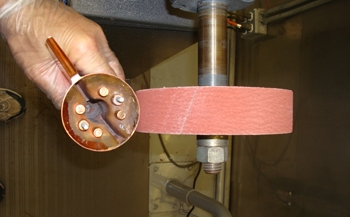

Using a belt grinder he shaves precisely where needed.

In addition some fine work is done to perfect the fit using a fordham tool with micro burr-tools.

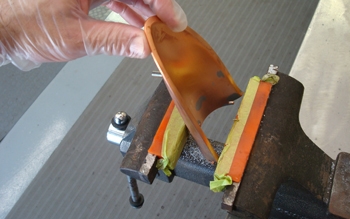

Next hand files are used on the holding slot

Final tweaking on the opening using a round file to make it fit.

A bit of hand sanding using 180 grit for a final fit.

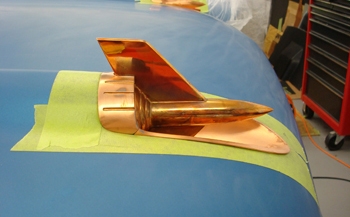

He holds it up and a nice razor blade gap shows it finished and ready for nickel and chrome.

He marks it where he is a satisfied as she is looking good.

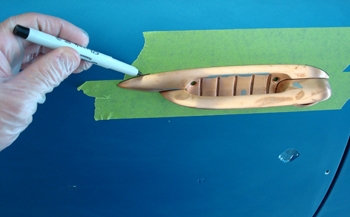

The door handles need tweaking to achieve our standard razor blade gaps desires.

As seen here she is looking good

Rockets stick up in to the air. The copper plating builds up on the edges and is a big part of the problem.

Being sure it is straight and fits the car is important.

Eric marks the locations he is happy with.

Points out a gap he wants to correct.

As seen she fits tight and right.

Starting to come out the gaps are being refinished.

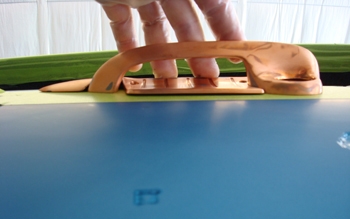

Hand sanding is required many times.

Each pice gets done.

Some times you can tweak pot metal in a vise with soft jaws as it is somewhat pliable if heated a bit.

Eric has been building, assembling and tweaking parts to fit so long that he just has the touch.

A bit more.

On to the Belt sander for a bit more still.

The bottom side needs just a hair to finish it.

Voila bad to the bone.

Just the way Jeff likes it dead on!

Fitting issues with the door handles and guards.

Major tweakage needed as these are repro items made in chin,tawin,japo or somewhere overseas?

Mark then do the duty.

Eric, you are a master, trained by the best to become the ultimate!

With details like this, one has to admit quality is taking place.

The fender extensions need work also but often it is not the copper that plates unevenly, sometimes paint and primer buildup affects the fit and it needs tweaking also.

This paint edge needed a bit of shaving.

A small wood block with some 180 grit makes short work of it. Being sure not to cut where it will not be covered by the trim is vital.

Just what the doctor ordered, a razor blade gap.

Qter panel extentions were blocked to remove the ripples they come with.

Some fine tweaking.

Nice.

Parts fitting to other parts such as this bumper are also tweaked to fit precisely.

Bumper part to bumper parts need grinding to fit also.

Dead on square, straight and true are normal everyday items done by our team.

Fitting back up light bezels, you name it we do it.

The bumper edges needed trimmed to be sure of clearance where they meet the gold belair grill.