1936 Truck - Hood

The fold up hoods of the 20's and 30's are very unstable. Getting them to line up right and work smoothly while staying ripple free is a major chore. At the very back the hood to the cowl needs shimming. This is done by raising the pivot bracket that holds the end of the hinge rod.

Niceee!!!!! Bob

The corner of the hood to cowl fit is way off. This has to be done on the cowl because the hood has to remain straight and level up to it.

Pie cut and sliced then tapped gently down in to place.

Gapped out on the back edge from one side to the other.

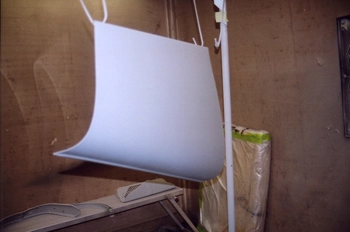

Hood sides were dipped in acid and are ready to prep.

Prime ready.

Hi build the tops.

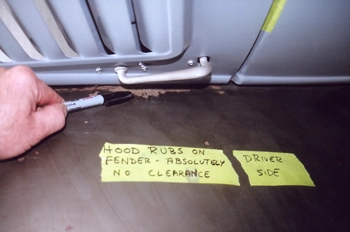

Hood sides barely clear the fenders so we will shrink them a bit to eliminate any paint scuffing when opening and closing the hood.

The latch assembly / spring was slightly heated to lessen the tension which allows us to pull down the hood and latch it a bit easier.

As seen Bob is shimming the hood and piano hinge as a unit for optimum results.

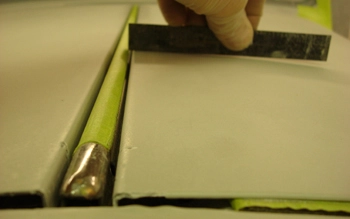

Time to weld the stainless piano hinge to the hood itself. We spot blasted the areas to be welded for max adhesion and minimal burn back.

Spot weld, cool and on to the next one to eliminate burning the primer.

Ground smooth we are ready for body work and final fit.