1928 International Truck - Door Supports

We built all the wood on this 28 Truck from scratch and the door supports for the window cranks were part of that challenge. We drew out our configurations on the correct thickness particle board as a template to check fit and alter anything needed. Then we transferred it to Red Oak.

Our templates are made and provide the results we are looking for. We laid it out on to the oak and started to cut out the unwanted sections.

We then clear coated the supports for protection and are ready to fit the cranks and attached them permanently to the doors.

The cranks were built from new MFG parts and then lengthened and or shortened where needed to achieve our results. As seen the glass run channel was tack welded on at the best spot to get full height and also enough to lower the glass to the edge of the door panel.

They are looking good and coming together.

Installed on to the truck we use acrylic sheeting as a glass mock up which enables us to trim to the desired shape for exact sizing. When this has been decided upon the glass will then be cut from these acrylic templates.

She looks good, goes up and down correctly and we are ready to work all the latches and stops on the outer frame.

The half round guide stops have to be installed before we refinish the door edges, so we carefully used a forester bit to drill out the round section in the center and then chisled 1/16th down around the outer perimeter to fit the parts.

She fits great and makes perfect contact keeping the door aligned as is her original intent.

The wood gets cut out to install the latch using a coping saw to trim unwanted materials and get her ready for installation.

The striker on the door gets the same treatment so we cut out the materials to allow for a flush fit to the door.

The side of the door also needs to be cut down a bit to allow full flush fit so the door panel will sit flush against the door.

Looks good, closes and we can now restore the catch by re-plating it .

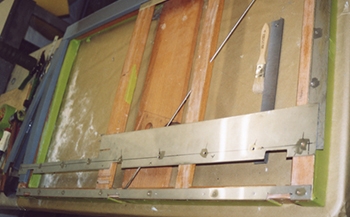

To shim the outer body skin and support the door for strength we fabbed some stainless strips to accomplish this feat.

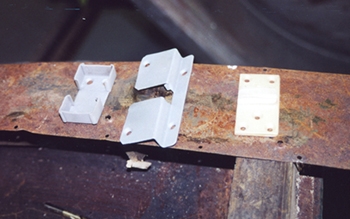

The original catch and striker are in rough shape so we will fab new ones.

We blasted what we were able to use and fabbed the rest to meet our requirements.

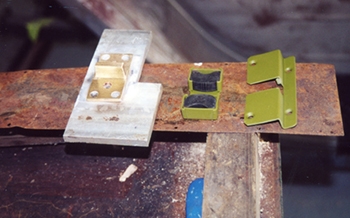

A new chunk of brass was formed and shaped to our needs as seen she is screwed down to a piece of aluminum. We then hand sanded it to finish the fit. Take note of the restored and fabbed parts in green zinc chromate with new rubber dove tails installed.